møbel

full circle (work in proooooogress)

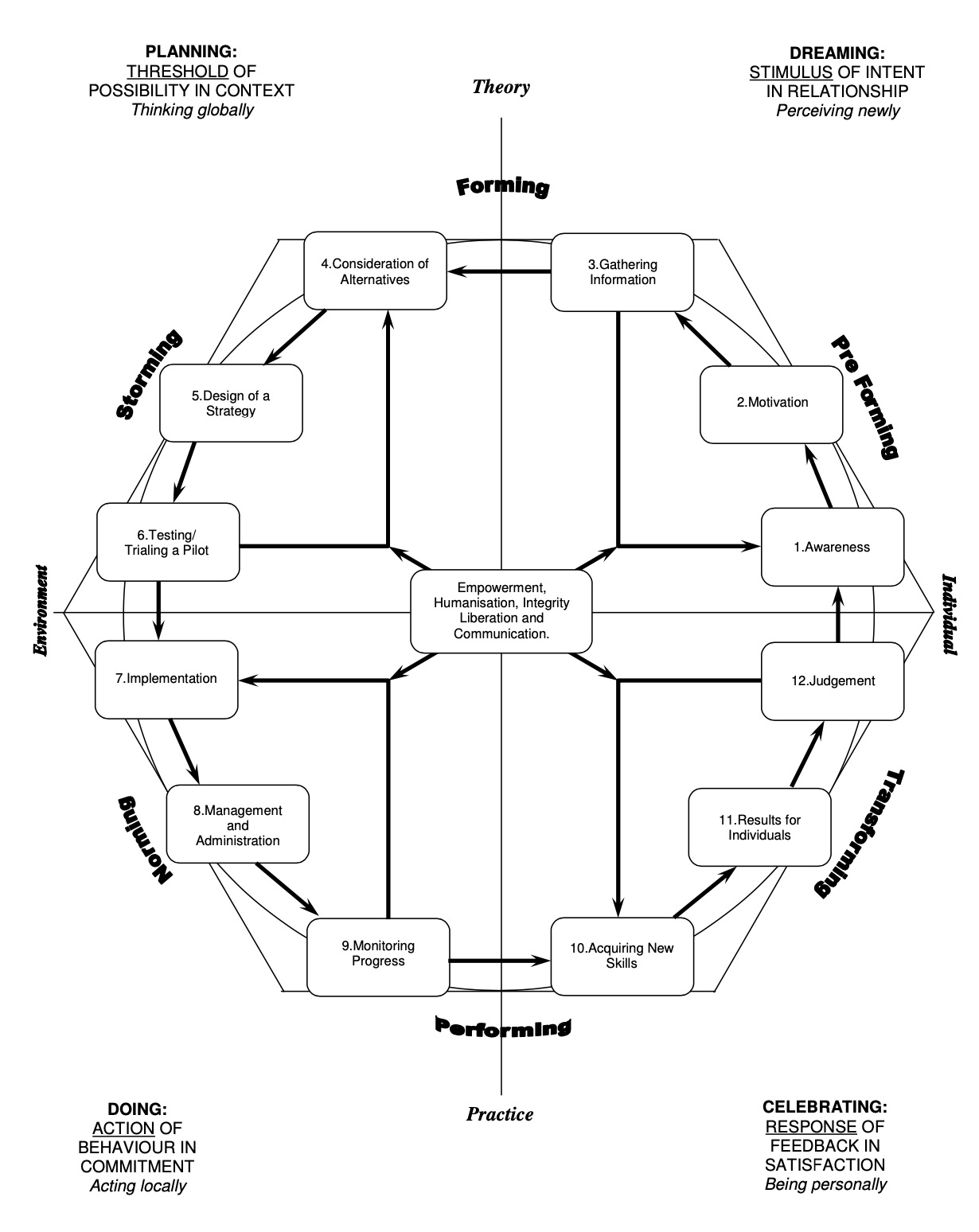

‘full circle’ is an open ended furniture project that follows the dragon dreaming project management method (John Croft - Gaia University in Western Australia )

pre-forming, storming, forming, norming, transforming and performing

Preforming - source material - spotted on an abandoned parking lot at Passo di Monterolo in the Marches in Italy. awareness and motivation - may the circle be unbroken

Forming - local wood supply from the west coast of norway - gathering information and consideration of alternatives

Storming - as part of a furniture design class at the Intsitue for Design at the University of Bergen - we have steam bent the ribs with the great help of bachelor design students at KMD and Levi Heyda from Kingston College of the Arts and Design in London.

design of a strategy - percieving newly - trailing a pilot

Forming - the preformed sculpture pieces were on display at old the linen mill in innvik as part of the group show ‘Hesten og Plysen’ curated by Veft in connection to the 50 year anniversary of the Norwegian Craft rtist Association - considering of

alternatives -

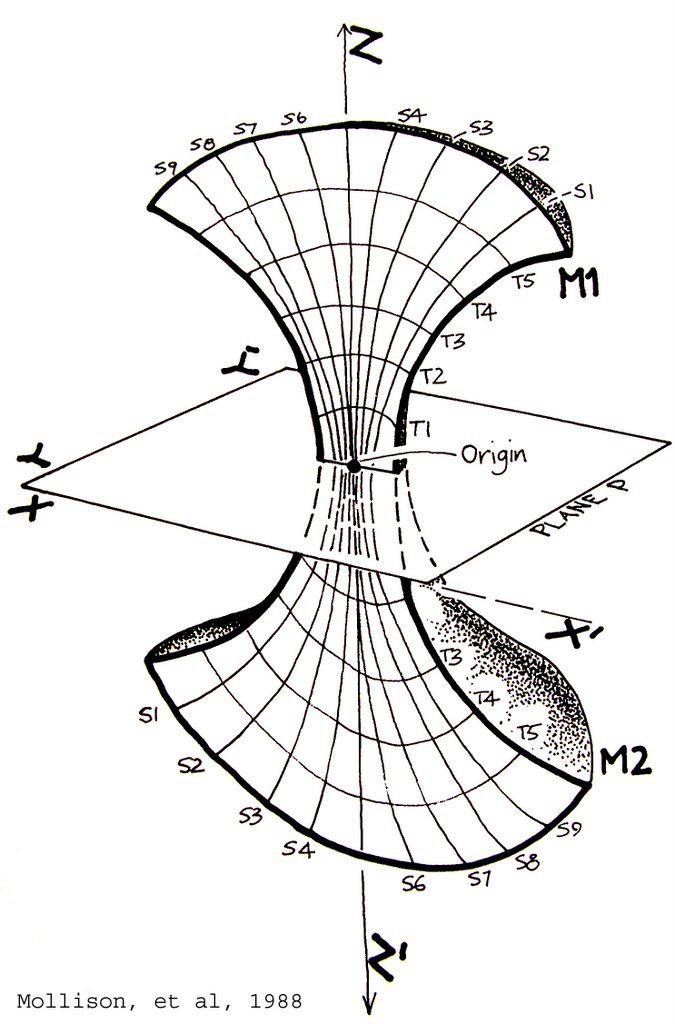

the so called core model, which translates to a 3 dimension torus, is a pattern that Bill Mollison (Permaculture: A Designers' Manual, pub.1988) spoke widely of because of its transformative energy

design of a strategy - inspired by the existing round metal park bench from italy, i am curious to make a wooden version of such design, exploring traditional craft techniques and different forms of collabortion - Storming

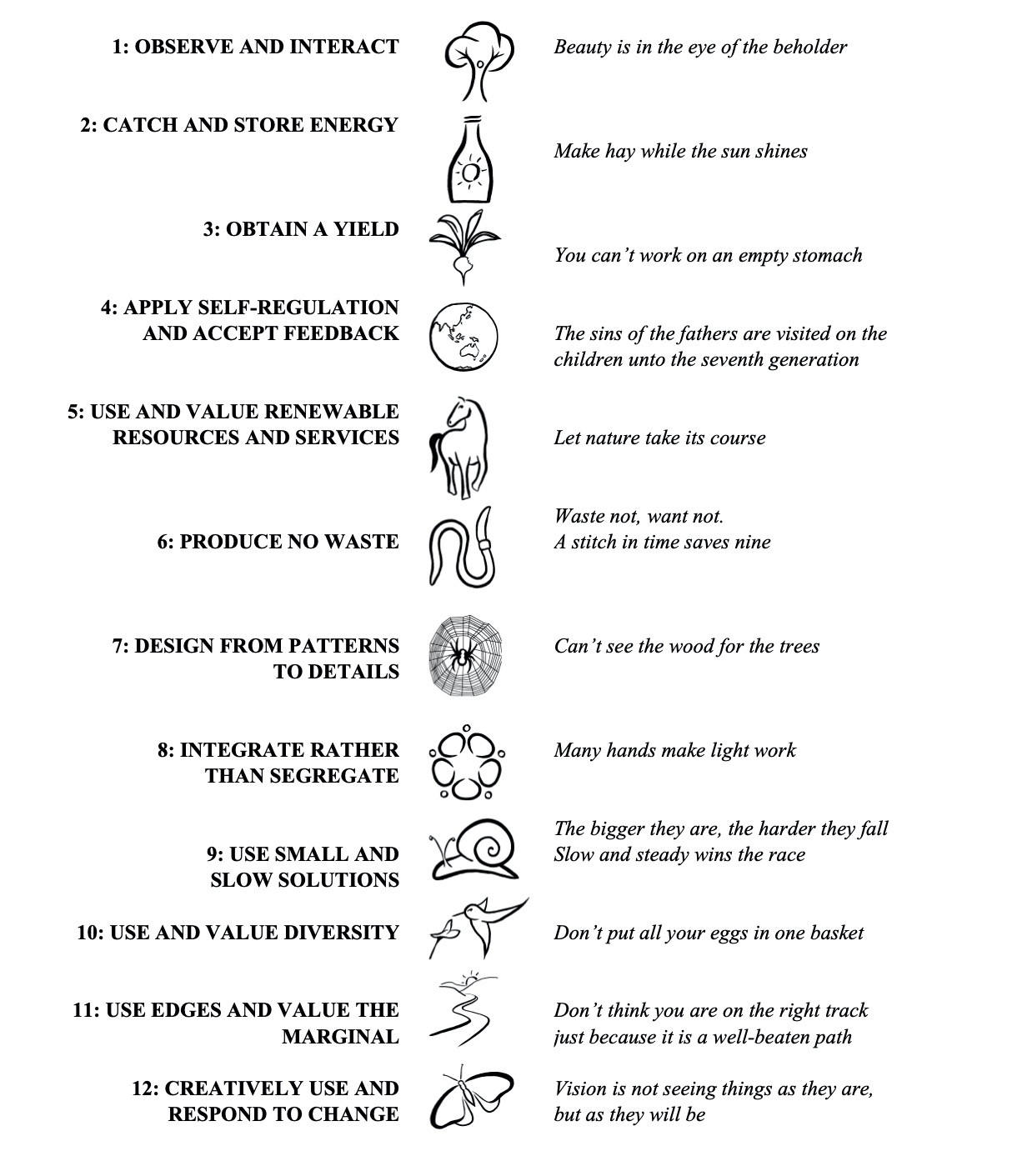

‘designing from patterns to details’ is a permaculture design priciple that helps me in this open-ended-hands-on-design-build-with the material-exhibit-refelct-design-work-in-progress-full circle-project

testing a pilot - treshold of possibility in context - thinking globally - acting locally

Norming - making decisions - crucial moment - from individual to environment -

from theory to practice

implementation - treshold of possibilities in context

norming - material - technology - time - space - feedback

form finding - reality check - ergonomy - construction - stabilty - materiality

material as a co - designer - “rules grow out of parts” - monitoring progress -

action of behaviour in comitment -

Performing - acquiring new skills - material propeties - constructive and decorative

Transforming - feedback and celebration - seeing is believing - spatial patterns

results for individuals - judgement - beeing personally

first testing and then tweaking for improvements

adjustment of curves, distances and heights

budget for full circle project - production, presentation and publication

monetary investment in nok (past)

transport of source material and wooden material 1.000

ratched belts for bending 1.000

bending jigs material and steamer 3.000

elm wood 5.000

transport to innvik 5.000

elm wood from Ørjan 3.000

3d drawing from Hannes 4.000

tools milling router bit 1.000

drill bits 30 mm 500

oil and wax 500

monetary investment in nok (future)

natural stone from solid tec in bergen 80.000

More elm wood for a straight version 3.000

presentation (zine & rom 8)

product pictures at KMD with photographer 5.000

Werkzine (brochure) - graphic designer 10.000

print jobb 250 - Werkzines 5.000

presentation in Rom 8 - posters 2.000

presentation (Milano design fair - one week end of April)

travel cost 5.000

transport cost 20.000

hotel 15.000

documentation (public pop up - pictures ) 5.000

rent for a stand in a design district 35.000

Sum 209.000

Sum total inkl unexpected costs 222.000

investment of time (past)

getting and handling the wood 8 marbles

making the bending jigs and prepping the elm wood 40 marbles

bending the woods with BA1 - four pieces each day 80 marbles

transport and install exhibition in innvik ullvarefabrikk 16 marbles

splitting, planing, milling and sending the pieces 80 marbles

designing the curve - redesigning the curves - 8 marbles

testing the bench at the capoeira baptism 4 marbles

investment of time (future)

making the vertical pieces in solid wood 24 marbles

more sanding - fine sanding everything 24 marbles

oiling the pieces 16 marbles

bee wax treatment 8 marbles

assembly 8 marbles

testing in nedre hall / eventuell rom 8 8 marbles

testing at bergen offentlig bibliotek 16 marbles

documentation 8 marbles

presentation for norheimsund 8 marbles

Werkzine (writing - compilling) 40 marbles

milan design week pop up 100 marbles

choooooosing you marbles

![]()

sand, glass, time, life, coulour, sound, weight, feel, look, transparency,

instagram: @philipp.vonhase